Why buy from us?

We offer competitive prices and quality services!

Ask a Question About This Product

- Stock: In Stock

- Model: 0.75KW

- Weight: 3.20kg

2. Shipping options include DHL, UPS, FedEx, and EMS.

3. Estimated delivery time for express shipping via DHL, UPS, FedEx, or EMS generally ranges from 3 to 10 business days, depending on the destination country.

4. Please verify your address thoroughly when placing your order.

5. Important for buyers: You are responsible for any tariffs on accessories. To potentially avoid these tariffs, you may choose EMS express shipping.

6. The shipping service is responsible for any accidents, delays, or other issues that may arise.

Returns:

We offer a 14-day return policy. If you wish to return an item, please contact us within 14 days and ensure that the package remains unopened. The buyer is responsible for the shipping costs for both the return and the initial delivery, as well as any applicable customs fees. Once we receive and inspect the product, we will process your refund within 24 hours.

For any quality issues that arise during normal use within the warranty period, we will repair the item free of charge. The buyer is responsible for the return shipping cost, while our company will cover the cost of re-shipping the repaired item.

0.75KW 1HP 400Hz VFD 3Ph 380V A510 TECO Compressors Punch Press

Application area:

Our TECO A510 is a versatile, high performance AC Drive that can control today's demanding motor driven applications. This highly flexible drive has multiple control modes to cover almost every motor driven application:

Compressors

High starting torque with sensorless vector mode

Stable torque at low speed

Metals processing including industrial saws, punch press, and

screw and bolt manufacturing

Attains the high torques required by these applications

Hardware design handles the high in-rush currents that are produced

High braking torque and regenerative overvoltage protection

Machine tool operations such as grinding, milling and lathes

Capable of output frequencies to 1200 Hz

Smooth operation and minimal ripple at any speed

High braking torque capabilities

High resolution analog input for demanding precision

Plastics and rubber process machines such as extruders and

rubber compounding

Smooth operation at low speeds

High starting torque to produce consistent product

Hardware design handles the high in-rush currents that are produced

Cranes, hoists, and materials handling

Four quadrant operation for motoring and regenerative situations

High torque for instant lifting

High braking torque, precise control and operation

Easily incorporates mechanical and safety interlocks

General Specifications

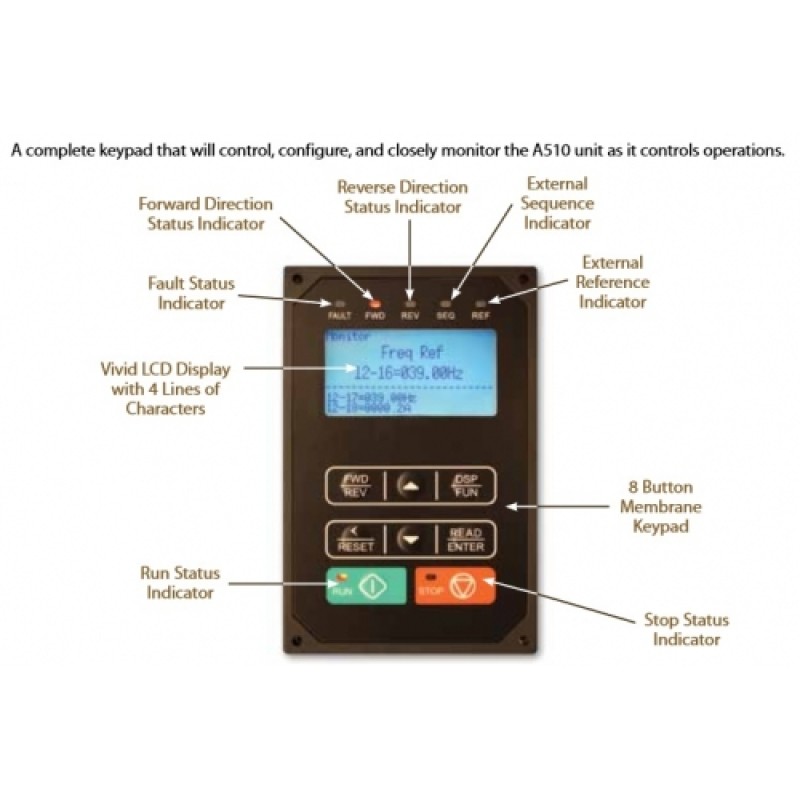

Operation mode | LCD keypad with parameter copy function (Optional Seven-segment display * 5 + LED keypad) |

Control mode | V/F, V/F+PG, SLV, SV, PMSV, PMSLV with space vector PWM mode |

Frequency control range | 0.1Hz ~ 599 Hz |

Frequency accuracy | Digital references: ±0.01 ?(-10 to +40°C) Analog references: ±0.1% (25°C ±10°C ) |

Speed control accuracy | ±0.1% ( vector control(SV))? ±0.5% ( vector control / open-loop) |

Frequency setting resolution | Digital references: 0.01Hz, Analog references: 0.06Hz/60Hz |

Output frequency resolution | 0.01Hz |

Inverter overload | Rated output current 150%/1 min, 200%/2sec (HD mode),120%/1 min (ND mode) |

Frequency setting signal | 0 to +10VDC / 4 to 20mA or -10V to +10VDC and pulse input command frequency |

Acceleration/deceleration time | 0.0 - 6000.0 second (separately set acceleration and deceleration time ) |

Voltage,frequency characteristics | Custom V/f curve based on parameters |

Main control functions | Auto tuning, Zero Servo, torque control, position control, Droop, Soft-PWM, over-voltage |

Other functions | Accumulated power-on / run time, 4 sets of fault history records and latest fault record state, |