Why buy from us?

We offer competitive prices and quality services!

Ask a Question About This Product

- Stock: In Stock

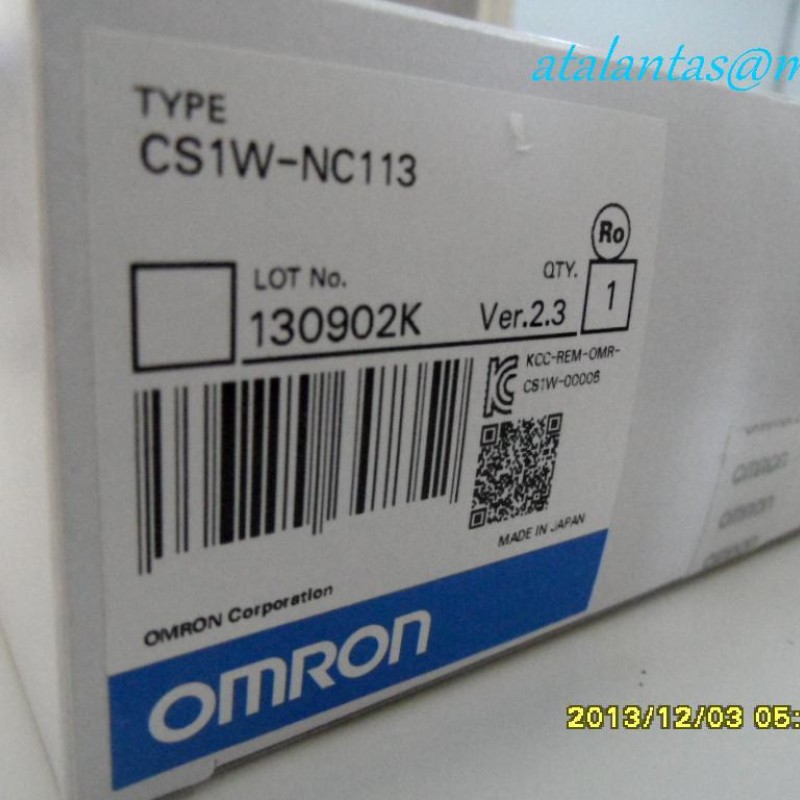

- Model: CS1W-NC113

- Weight: 2.00kg

2. Shipping options include DHL, UPS, FedEx, and EMS.

3. Estimated delivery time for express shipping via DHL, UPS, FedEx, or EMS generally ranges from 3 to 10 business days, depending on the destination country.

4. Please verify your address thoroughly when placing your order.

5. Important for buyers: You are responsible for any tariffs on accessories. To potentially avoid these tariffs, you may choose EMS express shipping.

6. The shipping service is responsible for any accidents, delays, or other issues that may arise.

Returns:

We offer a 14-day return policy. If you wish to return an item, please contact us within 14 days and ensure that the package remains unopened. The buyer is responsible for the shipping costs for both the return and the initial delivery, as well as any applicable customs fees. Once we receive and inspect the product, we will process your refund within 24 hours.

For any quality issues that arise during normal use within the warranty period, we will repair the item free of charge. The buyer is responsible for the return shipping cost, while our company will cover the cost of re-shipping the repaired item.

CS1W-NC113 PLC OMRON 1 Axis Position Control Unit Original brand new

Features

Two types to choose from: open collector output and line driver. Because both open collector output and line driver types feature 1-, 2-, and 4-axis models, the most appropriate model can be selected for the application at hand.

Positioning START occurs within 2 ms (maximum speed) after receiving a command from the Programmable Controller.

High-speed data transfer is possible using INTELLIGENT I/O WRITE (IOWR) and INTELLIGENT I/O READ (IORD) instructions.

Fine control from low to high speed (500 kpps max.) is possible in 1-pps units.

Positioning can be done from memory, by writing an operating pattern into the PCU memory in advance. Three position patterns − Terminating, Automatic, and Continuous − can be set with completion codes to respond to a wide range of operations. Positioning of up to 100 patterns (sequential data) per one axis can be possible.

Positioning (direct operation) can be done by direct PLC ladder commands for position data, speed data, and acceleration data. This simplifies control in situations when the target position and speed cannot be decided until immediately before operation begins, or when the target position and speed change due to other circumstances. The target position and speed can also be changed during operation.

Interrupt feeding moves the axis a specified amount, then stops it, in accordance with an interrupt input. High-speed (0.1 ms max.) processing of the interrupt input signal ensures high-precision interrupt positioning. This helps to maximize feeder precision.

Easy-to-Use positioning can be possible with versatile functions such as Teaching, Override, Backlash compensation, Zones, Forced interrupt and Acceleration/Deceleration curve.

Specification

Unit | Name | Specifications | No. of | Current | Model | Standards | ||

Control method/ | Number of | 5 V | 24 V | |||||

CJ1 | Position

| Open-loop control | 1 axis | 1 | 0.25 | --- | CJ1W-NC113 | UC1, CE |

2 axes | 0.25 | --- | CJ1W-NC213 | |||||

Dimension